For every single colour to be printed, a plate is made and eventually placed on a cyndrical tube which is placed in the printing press. To make a full picture, despite printing on adaptable film or corrugated paper, the picture moved from each plate needs to register precisely with the photos transferred from the various other colors. To ensure an accurate image is made, mounting marks are made on the flexographic plates. Unique equipment is produced mounting these plates on the printing cyndrical tubes to maintain registration.

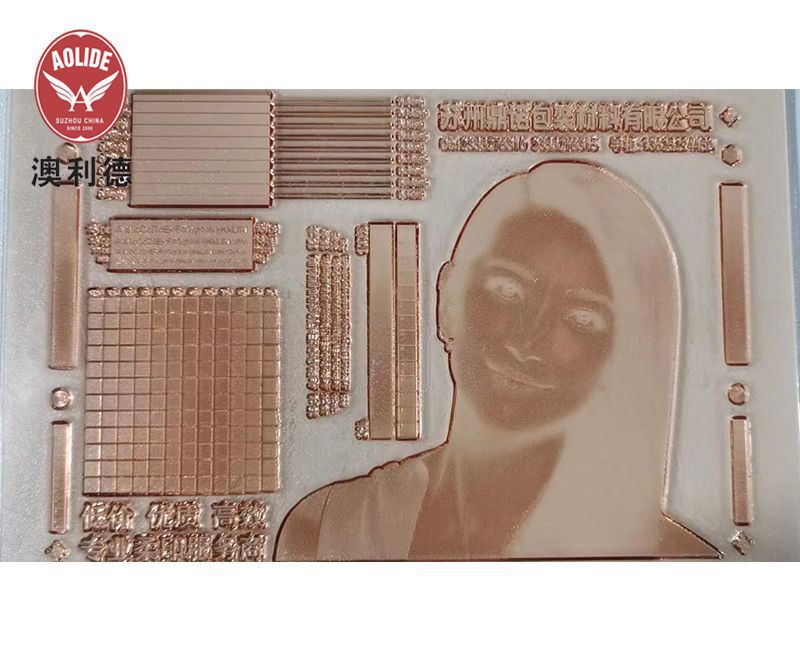

A few remarkable honors from FTA consist of Silver Award for printing plates made for Packaging Firm of America and Silver in the Direct Print Corrugated group for our job with the Scotch 3M Padding Cover Box. Dynamic Passes Away with Independent II and Jeptha Creed teamed up to create the award-winning Jeptha Creed Four Grain Mash Costs Bourbon Bourbon box that won in the Incorporated Corrugated, Display classification. The first action is to produce a steel plate out of the unfavorable of our preliminary photo via a presentation procedure. This steel plate in relief is after that utilized in the second step to create the mold that can be in bakelite board or perhaps glass or plastic, with a very first molding procedure. Once cooled, this master mold will press the rubber or plastic compound with a second molding procedure to develop the printing plate or saying.

With this innovation, Mosstype Company made significant developments in rubber plate making, enabling reliable procedures to be developed for aniline printing, which was the forerunner to flexography. The combination of the 2 direct exposures enables an exact recreation of fine relief components and high-resolution surface area screening onto the ended up plate. With an optimum plate size of 1270 x 2032 mm, the system is huge enough to handle all applications. Our photopolymer plate technology and strategic collaborations ensure the high quality print you desire, delivered when you need it. Making use of liquid platemaking in your procedure has a substantial number of ecological benefits. For more details on the fluid photopolymer plates that work well within your market, please see the Liquid Selection Guides listed below.

Also after the Fda approved the aniline procedure in 1949 utilizing brand-new, risk-free inks, sales remained to decrease as some food producers still refused to take into consideration aniline printing. Anxious concerning the picture of the market, product packaging reps made a decision the process needed to be relabelled. Plates installed onto steel or brass backing make plate adjustments quick, easy, and tidy. Steel-backed plates are generally utilized on print drums covered with magnetic material so that plates can be promptly put anywhere on the drum. Brass back passes away mount with screws or clamps on print wheels to protect against motion during printing.

Flexography is a type of printing procedure which makes use of a versatile alleviation plate. It is essentially a contemporary variation of letterpress, advanced with broadband rotary capability, which can be utilized for printing on practically any kind of kind of substrate, including plastic, metal movies, cellophane, and paper. It is extensively utilized for printing on the non-porous substrates required for different sorts of food product packaging.

Our photopolymer plates and newspaper plates give phenomenal remedies that supply top notch graphics capacities to all kinds of product packaging and newspaper printing applications. The nature and demands of the printing process and the application of the printed item figure out the fundamental residential or commercial properties required of flexographic inks. If you enjoyed this post and you would such as to obtain additional info concerning Psdtutz.Com kindly check out our web site. Measuring the physical buildings of inks and recognizing just how these are impacted by the choice of active ingredients is a large part of ink innovation.

The image locations are increased above the non photo areas on the rubber or polymer plate. To prevent getting a last product with a smudgy or lumpy appearance, it should be ensured that the quantity of ink on the printing plate is not extreme. The physician blade gets rid of excess ink from the anilox roller before inking the printing plate.

The washout remedy can be water or solvent, depending on the kind of plate material. The unexposed areas of the polymer are then cleaned away from the plate base, through a washout brush.

For every colour to be published, a plate is made and ultimately put on a cyndrical tube which is positioned in the printing press. To make a full picture, regardless of printing on adaptable film or corrugated paper, the picture moved from each plate has to sign up exactly with the photos transferred from the other colors. With this development, Mosstype Corporation made massive advances in rubber plate production, enabling efficient procedures to be developed for aniline printing, which was the precursor to flexography. Steel-backed plates are generally used on print drums covered with magnetic material so that plates can be quickly put anywhere on the drum. Our photopolymer plates and paper plates provide remarkable solutions that deliver high-grade graphics capabilities to all types of product packaging and paper printing applications.

For every colour to be published, a plate is made and ultimately put on a cyndrical tube which is positioned in the printing press. To make a full picture, regardless of printing on adaptable film or corrugated paper, the picture moved from each plate has to sign up exactly with the photos transferred from the other colors. With this development, Mosstype Corporation made massive advances in rubber plate production, enabling efficient procedures to be developed for aniline printing, which was the precursor to flexography. Steel-backed plates are generally used on print drums covered with magnetic material so that plates can be quickly put anywhere on the drum. Our photopolymer plates and paper plates provide remarkable solutions that deliver high-grade graphics capabilities to all types of product packaging and paper printing applications.